Shuangyang Group is a high-tech enterprise that integrates R&D, production and sales. The company has a complete management system, so after the company’s sales clerk receives the customer’s ED1-2 order, multiple departments need to cooperate to complete the order production.

Planning Department

Conduct price review, and the merchandiser will input product quantity, price, packaging method, delivery date and other information into the ERP system

Review department

After passing the review of multiple parts, it will be sent to the production department by the system.

Production department

The production department planner develops the master production plan and material requirements plan based on the sales order, and passes them to the production workshop and purchasing department.

Purchasing Department

Supply copper parts, electronic components, packaging, etc. according to planned requirements, and arrange production in the workshop.

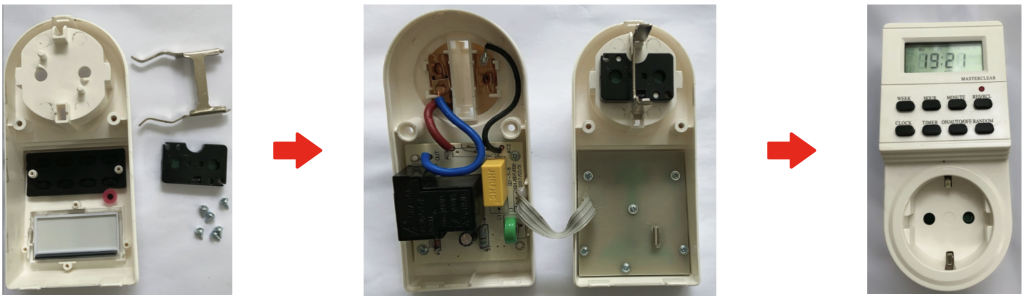

Production Process

Inspection Process

First Article Inspection

Inspection

Product model

The content is consistent with the order

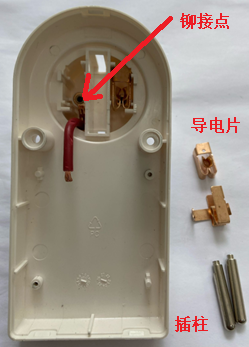

Welding points

No virtual welding or missing welding

Exterior

No shrinkage, debris, flash, burrs, etc

LCD screen

There is no debris inside, it shows blurred overlapping images, and the strokes are complete

Safety film

The single insertion post cannot be inserted open and can be reset flexibly

Reset button

When pressed, all data can be cleared normally and timing starts from the system default settings

Function keys

The keys are not loose or cracked and are elastic, and the key combinations are flexible and effective

Insertion and extraction force

The socket is plugged and unplugged 10 times, the distance between the grounding brackets is between 28-29mm, and the plug-in and pull-out force of the socket is minimum 2N and maximum 54N

Finished product inspection

Output performance

Place the product on the test bench, turn on the power and plug in the output indicator light. It must be clearly on and off. There is output when "ON" and no output when "OFF".

Timing function

Set 8 sets of timer switches, with switching actions at intervals of 1 minute. The timer can make switching actions according to the setting requirements

Electrical strength

The live body, ground terminal, and shell can withstand 3300V/50HZ/2S without flashover or breakdown

Reset function

When pressed, all data can be cleared normally and timing starts from the system default settings

Travel time function

After 20 hours of operation, the travel time error does not exceed ±1min

Packaging and storage

Sales, Delivery and Service

After-sales service

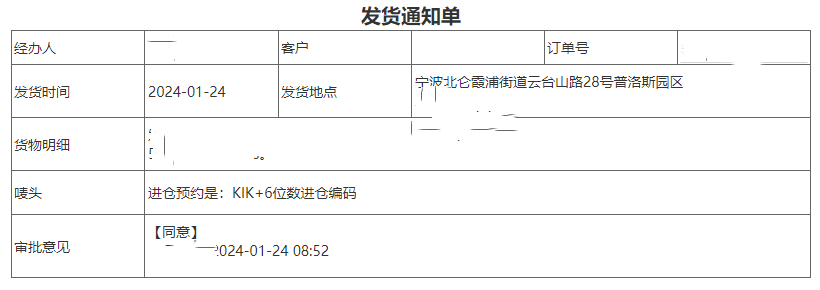

Export products such as one-week mechanical timers are transported by the freight forwarding company to the Ningbo Port terminal for warehousing, waiting for container loading. The land transportation of the products is completed, and the sea transportation is the responsibility of the customer.

First Article Inspection

Packaging and storage

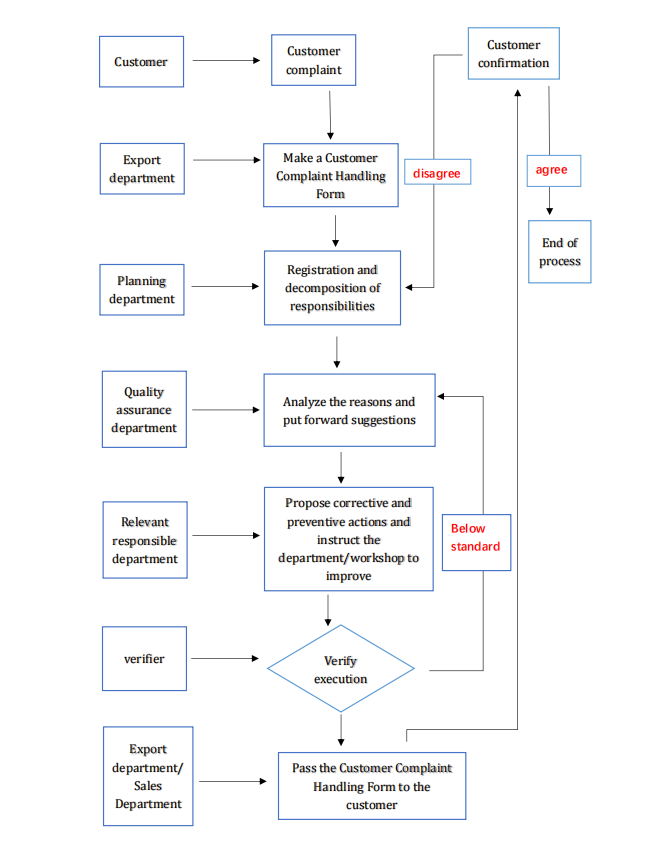

After the planning department confirms, the quality assurance department will analyze the reasons and make suggestions. The planning department decomposes responsibilities based on the cause analysis and suggestions and passes them to relevant departments. The heads of relevant responsible departments propose corrective and preventive measures and instruct their departments/workshops to improve.

The verification personnel check the implementation status and feedback the information to the planning department, and the planning department passes the original “Customer Complaint Handling Form” to the import and export department and sales department. The export department and sales department will feedback the processing results to customers.