銷售流程

· 當銷售人員收到客戶的 XP15-D 電纜捲盤訂單時,他們會將其提交給計劃部門進行價格審核。

· 然後,訂單處理人員將電纜捲筒數量、價格、包裝方法和交貨日期輸入 ERP 系統。銷售訂單經過生產、供應、銷售等各部門審核後,由系統下發給生產部門。

· 生產計劃員根據銷售訂單創建主生產計劃和物料需求計劃,並將這些信息傳遞給車間和採購部門。

· 採購部按計劃供應鐵捲、鐵架、銅件、塑料、包裝材料等材料,車間安排生產。

· 然後,訂單處理人員將電纜捲筒數量、價格、包裝方法和交貨日期輸入 ERP 系統。銷售訂單經過生產、供應、銷售等各部門審核後,由系統下發給生產部門。

· 生產計劃員根據銷售訂單創建主生產計劃和物料需求計劃,並將這些信息傳遞給車間和採購部門。

· 採購部按計劃供應鐵捲、鐵架、銅件、塑料、包裝材料等材料,車間安排生產。

生產流程

車間收到生產計劃後,指導物料管理員收集物料並安排生產線。 XP15-D電纜捲筒的主要生產步驟包括注塑成型、插頭線加工、電纜捲筒組裝、包裝入庫。

注塑成型

使用注塑機將PP材料加工成工業電纜捲盤面板和鐵架手柄。

插頭線加工

剝線

使用剝線機去除電線的護套和絕緣層,露出用於連接的銅線。

鉚

使用鉚接機將剝好的電線與德式插頭芯壓接。

注塑插頭

將壓接的芯插入模具中進行注射成型以形成插頭。

Cable Reel Assembly

Reel Installation

Fixing the XP31 rotating handle onto the XP15 reel iron plate with a round washer and self-tapping screws, then assembling the reel iron plate onto the XP15 reel and tightening with screws.

Iron Frame Installation

Assembling the iron reel onto the XP06 iron frame and securing it with reel fixtures.

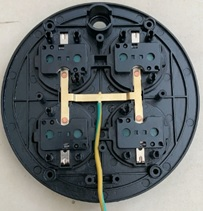

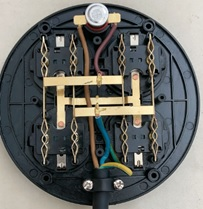

Panel Assembly

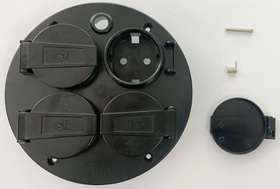

Front: Assembling the waterproof cover, spring, and shaft onto the German-style panel.

Back: Installing the grounding assembly, safety pieces, temperature control switch, waterproof cap, and conductive assembly into the German-style panel, then covering and securing the back cover with screws.

Panel Installation

Installing sealing strips on the XP15 reel, fixing the German-style panel D onto the XP15 reel with screws, and securing the power cord plug onto the iron reel with cable clamps.

Cable Winding

Using an automatic cable winding machine to wind the cables onto the reel evenly.

Packaging and Storage

After industrial retractable cable reel inspection, the workshop packages the products, which includes labeling, bagging, placing instructions, and boxing, then palletizes the boxes. Quality inspectors verify that the product model, quantity, labels, and carton markings meet requirements before storage.

檢驗流程

Indoor Cable Reel inspection occurs concurrently with production, including initial piece inspection, in-process inspection, and final extension cord auto reel inspection.

Initial Piece Inspection

The first electrical cable reel of each batch is inspected for appearance and performance to identify any factors affecting quality early and prevent mass defects or scrap.

In-Process Inspection

Key inspection items and criteria include:

· Wire stripping length: must comply with production process requirements.

· Small reel installation: per production process.

· Riveting and welding: correct polarity, no loose wires, must withstand 1N pull force.

· Panel installation and reel assembly: per production process.

· Assembly check: per production process requirements.

· High voltage test: 2KV, 10mA, 1s, no breakdown.

· Appearance check: per production process.

· Drop test: no damage from a 1-meter drop.

· Temperature control function: pass the test.

· Packaging check: meet customer requirements.

· Wire stripping length: must comply with production process requirements.

· Small reel installation: per production process.

· Riveting and welding: correct polarity, no loose wires, must withstand 1N pull force.

· Panel installation and reel assembly: per production process.

· Assembly check: per production process requirements.

· High voltage test: 2KV, 10mA, 1s, no breakdown.

· Appearance check: per production process.

· Drop test: no damage from a 1-meter drop.

· Temperature control function: pass the test.

· Packaging check: meet customer requirements.

Final XP15 reel Inspection

Key inspection items and criteria include:

· Withstand voltage: 2KV/10mA for 1s without flickering or breakdown.

· Insulation resistance: 500VDC for 1s, not less than 2MΩ.

· Continuity: correct polarity (L brown, N blue, yellow-green for grounding).

· Fit: suitable tightness of plugs into sockets, protection sheets in place.

· Plug dimensions: per drawings and relevant standards.

· Wire stripping: as per order requirements.

· Terminal connections: type, dimensions, performance as per order or standards.

· Temperature control: model and function tests pass.

· Labels: complete, clear, durable, meet customer or relevant requirements.

· Packaging printing: clear, correct, meet customer requirements.

· Appearance: smooth surface, no defects affecting use.

· Withstand voltage: 2KV/10mA for 1s without flickering or breakdown.

· Insulation resistance: 500VDC for 1s, not less than 2MΩ.

· Continuity: correct polarity (L brown, N blue, yellow-green for grounding).

· Fit: suitable tightness of plugs into sockets, protection sheets in place.

· Plug dimensions: per drawings and relevant standards.

· Wire stripping: as per order requirements.

· Terminal connections: type, dimensions, performance as per order or standards.

· Temperature control: model and function tests pass.

· Labels: complete, clear, durable, meet customer or relevant requirements.

· Packaging printing: clear, correct, meet customer requirements.

· Appearance: smooth surface, no defects affecting use.

Packaging and Storage

After final inspection, the workshop packages the industrial cord reels as per customer requirements, labels them, places paper cards and boxes them, then palletizes the boxes. Quality inspectors verify the product model, quantity, labels, and carton markings before storage.

Sales Shipment and After-Sales

Sales Shipment

The sales department coordinates with customers to confirm the final delivery date and fills out a delivery notice in the OA system, arranging container transportation with a freight company. The warehouse administrator verifies the order number, product model, and shipment quantity on the delivery notice and processes the outbound procedures. For export products, the freight company transports them to Ningbo port for loading onto containers, with the sea transportation handled by the customer. For domestic sales, the company arranges logistics to deliver the products to the customer-specified location.

After-Sales Service

In case of customer dissatisfaction due to industrial extension cord reel quantity, quality, or packaging issues, complaints can be made via written or telephone feedback, with departments following the customer complaint and return handling procedures.

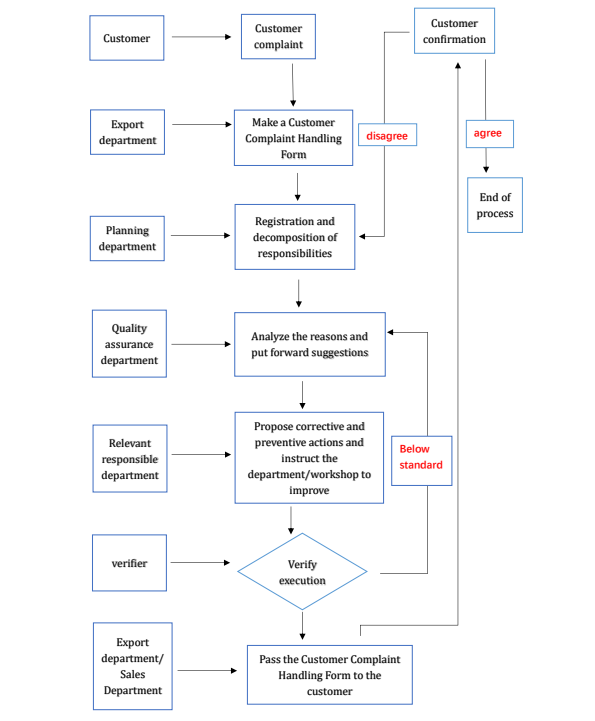

Customer Complaint Process:

The salesperson records the complaint, which is reviewed by the sales manager and passed to the planning department for confirmation. The quality assurance department analyzes the cause and suggests corrective actions. The relevant department implements the corrective actions, and the results are verified and communicated back to the customer.

Customer Return Process:

If the return quantity is ≤0.3% of the shipment, the delivery personnel return the products, and the salesperson fills out the return handling form, which is confirmed by the sales manager and analyzed by the quality assurance department. If the return quantity is >0.3% of the shipment, or due to order cancellation causing stockpile, a bulk return approval form is filled out and approved by the general manager.